Factory

Introduction

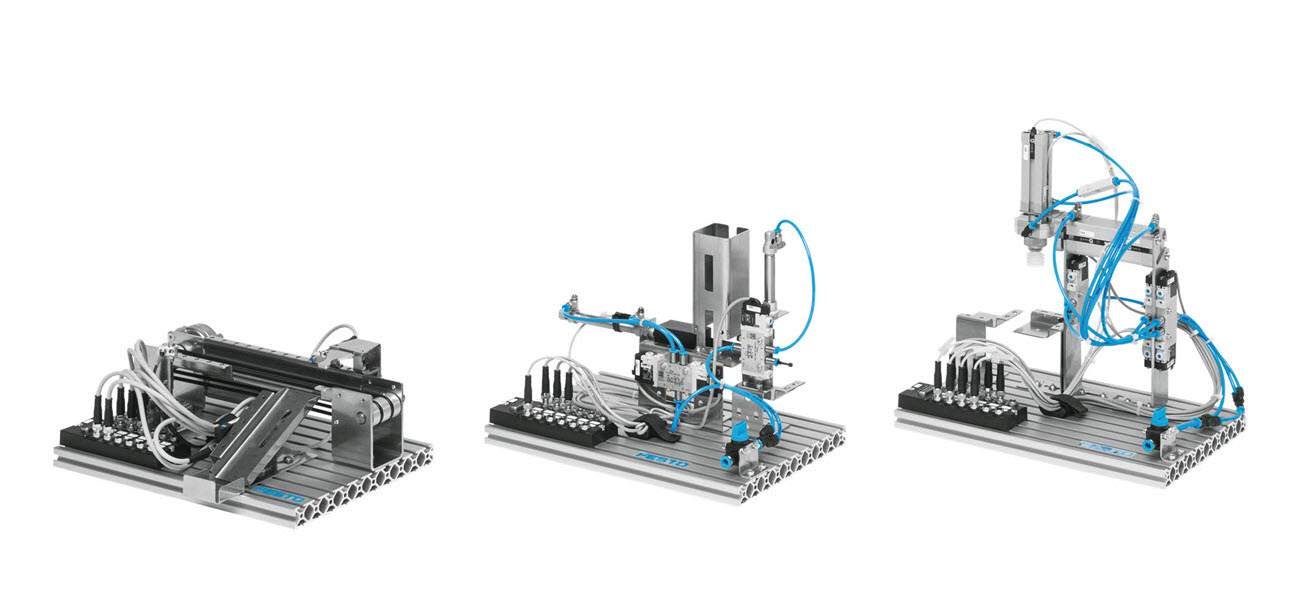

In this project, we simulated the control of a real-world factory production line using the Festo MecLab system. These compact, modular units replicate industrial processes on a smaller scale, allowing us to implement and test control logic for tasks such as storage, transport, sorting, and manipulation of workpieces, just as would occur in a fully automated factory environment.

MecLab Festo Stations

Festo MecLab is a modular mechatronics training system that includes scaled-down industrial automation models. These models replicate real-world industrial processes in a compact, educational format. It is divided into three systems :

- Stacking Magazine Station

- Conveyor Station

- Pick-and-Place Station

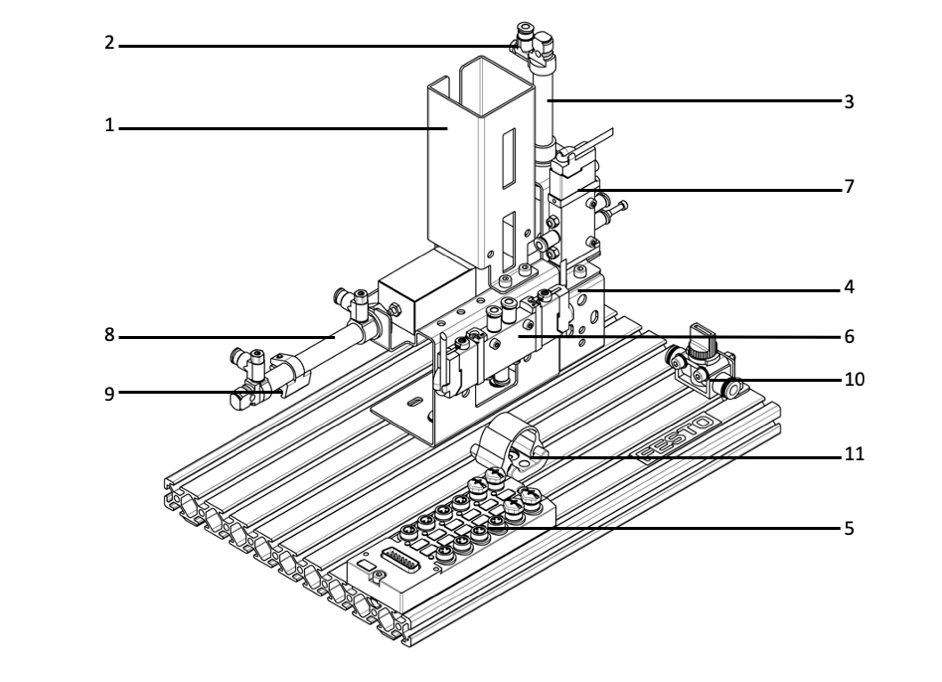

Stacking Magazine Station

It stores workpieces, transfers them, and can press or stamp them as needed. The process mimics real-world scenarios where raw materials or semi-finished products are organized and fed into production efficiently. It uses components like pneumatic cylinders, magnetic proximity sensors, and solenoid valves to manage the workflow, providing a practical understanding of automated storage systems.

Key Components

- Pneumatic cylinder (pushes buckets)

- Optical sensors for object detection

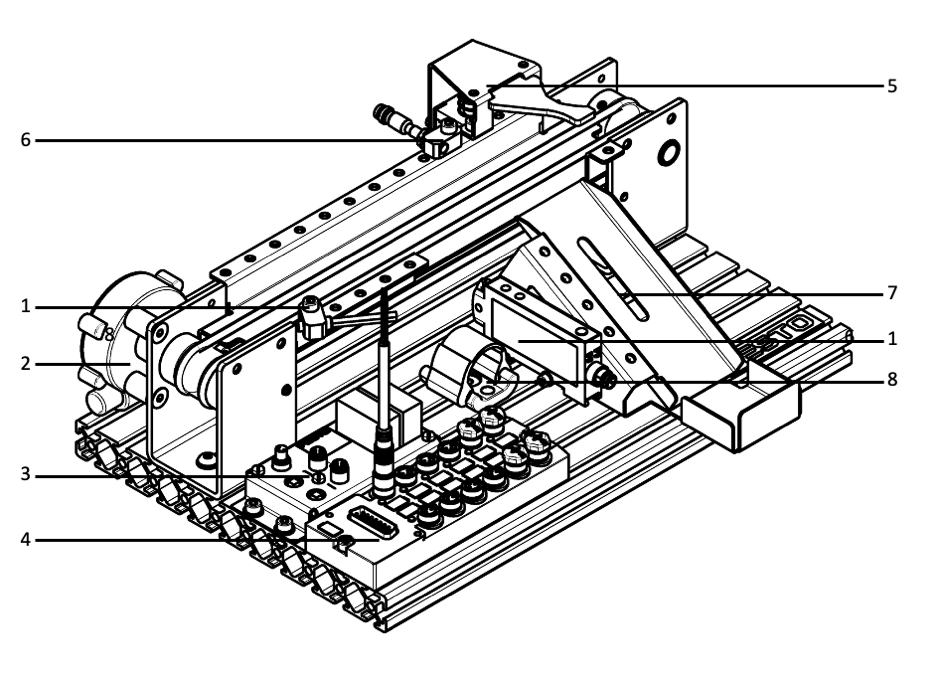

Conveyor Station

The Conveyor station replicates industrial workpiece transport, a common process in production lines. It can move workpieces forward or backward, detect them, and sort them by color using sensors. This station demonstrates the principles of material transport, classification, and sorting, which are critical in manufacturing. Its drive motor and sensors allow students to experiment with control logic and automation workflows, such as those interfaced via OPC UA in a factory setup.

Key Components

- Motor-driven conveyor belt

- Sensors (optical/inductive) for object detection

- Actuators for sorting/diverting objects

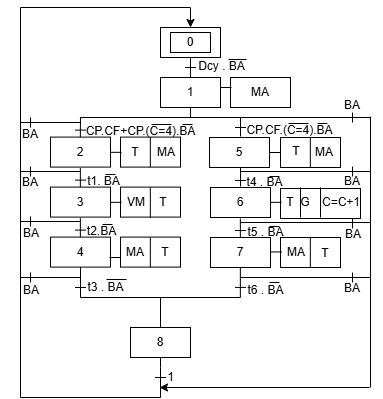

And the Grafcet that will be controling this station is as showen below :

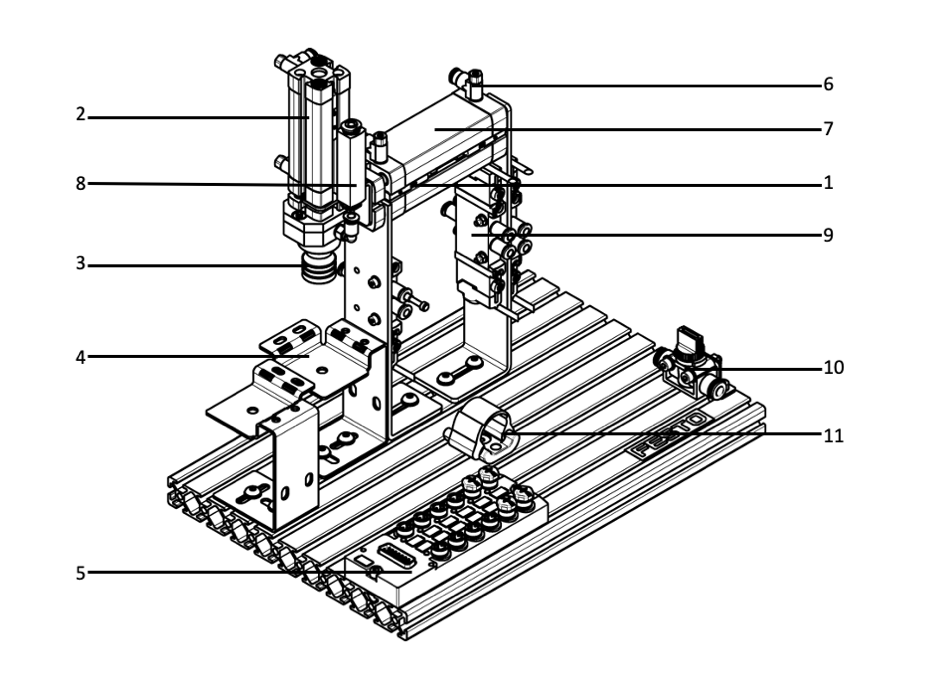

Handling Station

Focused on pick-and-place operations, the Handling station uses pneumatic cylinders with plain-bearing guides and a vacuum gripper to manipulate workpieces across two axes. It mirrors real-world handling systems used in assembly or sorting tasks, teaching students how to control motion and manage workpiece placement. This station is particularly relevant for understanding robotic automation and precision in industrial processes.

Key Components

Pneumatic gripper Linear axes (X-Y-Z movement) Sensors for object detection

Conclusion

Through the integration and control of the MecLab Festo stations, we successfully replicated an automated production line, and we’ll see how can control it in the next chapter.